Home > Food Processing > Automatic High Quality Inflating Snacks Production Line

Automatic High Quality Inflating Snacks Production Line

March 8, 20231.What Is The Automatic High Quality Puffed Food Production Line?

Puff snack machine can use corn flour,rice flour,wheat flour and other grain powder as raw materials, to produce different shape puff snacks by changing the extruder mould, such as chips, ball, ring, stick, flake, flower shapes etc. Puff Snack Machine adopt advanced extrusion technology with high efficiency instead of traditional steam boiling process. It has features of continuous working,stable performance and reasonable design.

2.Automatic Inflating SnacksProduction Line Components

|

Automatic Inflating Snacks Production Line Components

|

Mixer→Screw Conveyor→Twin-Screw Extruder→Hoister→Multi-Layer Oven→ Flavoring Line |

|

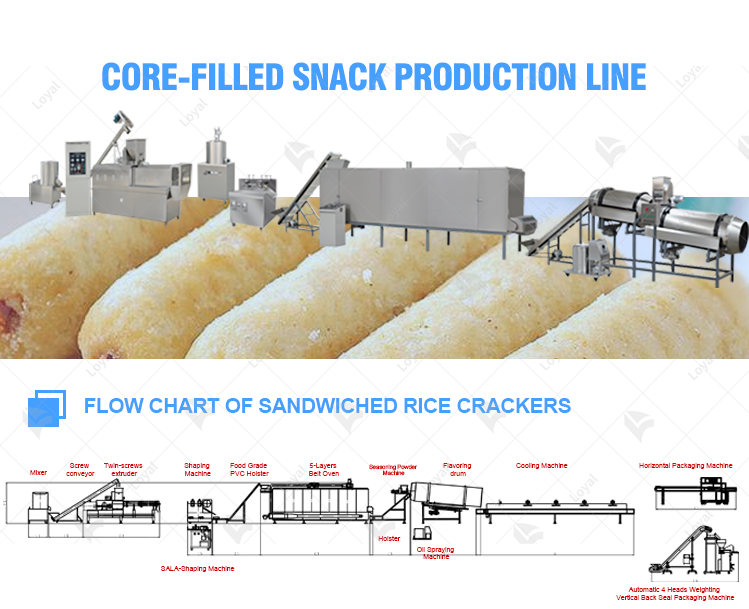

Automatic Core Filling Production Line |

Mixer→Screw Conveyor→Twin-Screw Extruder→ Core Filler→Multi-Function Shaper→Hoister→Multi-Layer Oven→ Flavoring Line |

3.Automatic Inflating SnacksProduction Line Components Production Line Process

| Name | Function |

| Mixer |

Mix the raw materials (corn flour, rice flour, flour, etc.) and add a certain amount of water to mix well. |

| Feeder |

use the motor as the power for screw conveying, and transport the mixed raw materials to the feeding hopper of the extruder to ensure convenient and fast feeding. |

| Twin-screw extruder |

according to the output of the production line, different types of extruder are selected. The output can vary from 100kg/h to 300kg/h. The raw materials can be corn flour, rice flour, flour, grain flour, etc. as raw material. |

| Core filler |

When the extruder produces a hollow tube, the core material is injected instantly, which can be injected into peanut butter, chocolate sauce, syrup, etc. |

| Multi-function shaper |

cut off the rice cracker with core material or shape it, the size of the rice cracker can be adjusted between 2cm-20cm. |

| Hoistor |

transports rice crackers to the oven. |

|

Oven/Dryer |

Most of the dryer are electric dryers. The temperature is adjusted between 0-200 degrees through the control cabinet. The interior is a stainless steel double-layer mesh bag. The baking time can be adjusted according to the speed. The material penetrates to a certain extent to increase the taste, while reducing the moisture of the material and increasing the shelf life. |

| Flavoring line |

There are octagonal, cylinder, single-roller, and double-roller seasoning lines, which are configured according to the output and product properties, as well as oil spraying, sugar spraying, and coating equipment. |

4.Automatic Inflating SnacksProduction Line Components Production Line Product Parameters

| Item No. | Installed Power |

Power Comsumption |

Capacity |

Dimension |

| LY-65 | 74KW | 52KW | 100-150kg/h | 17*1.3*2.2m |

| LY-70 | 105KW | 75KW | 200-260kg/h | 20*1.5*2.2m |

| LY-85 | 205KW | 150KW | 400-500kg/h | 30*1.5*2.6m |

5.Automatic Inflating SnacksProduction Line Components Production Line Advantages

Automatic inflating snacks production line components Production line is characterized by many models, flexible configuration, wide range of raw materials, many kinds of products, simple operation and high degree of automation.

6.Automatic Inflating Snacks Production Line Components Production Line Applications

Automatic inflating snacks production line components Production line can produce core-filled snacks, rice filled bar, puffed rice crackers, rice crackers, nutritious breakfasts, corn flakes, etc. and other products.

- Telephone+8613256674591

- Email[email protected]

- WhatsApp+8613256674591

- WeChat13256674591

- AddressC623, Jiahui Global Plaza, No. 548, Beiyuan Street, Tianqiao District, Jinan City, Shandong Province

- Factory AddressADD -300m North of Zhangxia Industrial Park, Binhe Road, Zhangxia Town, Changqing District, Jinan