Home > Food Processing > Bread Crumb Production Line

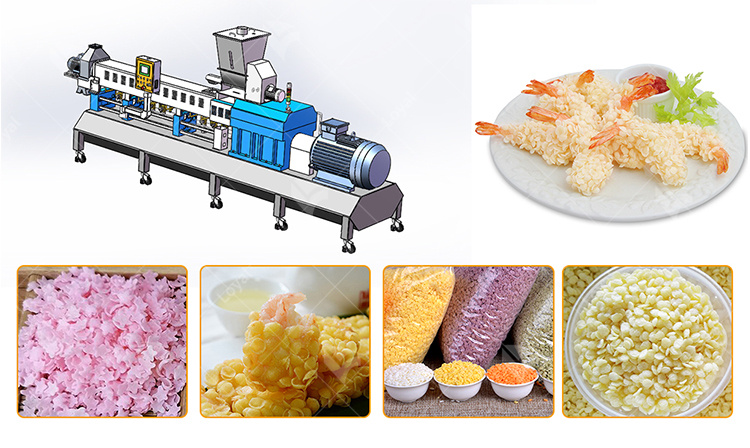

Bread Crumb Production Line

May 25, 2023The bread crumb production line is a production system designed for processing bread into bread crumbs. It is used in commercial and industrial food processing operations. A breadcrumb production line usually consists of several machines including bread crushers, flour mixers, feeders and conveyor belts. First use a bread crusher to break the bread into small pieces. The small pieces are then mixed with flour and other ingredients in a flour mixer to form a dough. This dough is then fed into a feeder and onto a conveyor belt where it is cut, dried and sieved to produce crumbs. Breadcrumb lines can be customized to meet the specific needs of food processors. It is an efficient automated system that can produce large quantities of breadcrumbs in a short period of time. The resulting breadcrumbs are used as a coating for fried foods, as a topping for casseroles and other dishes, among other foods.

The Flowchart Of Bread Crumb Process Line:

1.Mixing — 2.Screw Conveyor — 3.Twin Screw Extruder — 4.Pulling And Cutting Machine — 5.Hoister — 6.Multi-Layer Oven — 7.Hoister — 8.Crush Machine — 9.Viberate Sizer — 10.Packaging

The Introduction Of The Bread Crumb Process Line:

1.Mixer: Mix raw materials and a certain amount of water and stir well.

2.Feeding Machine:The motor drives the screw conveyor to transport the mixed raw materials to the feed hopper of the extruder.

3.Extruder:In high pressure environment, produce strip products. The control cabinet of the bulking machine can ensure the stability and safety of the high-pressure environment, but also can monitor the various parameters of the production process.

4.Pulling And Cutting Machine:The long strip product cut into short strips. Cutting machine can ensure that the production of products uniform size, and have a good appearance.

5.Hoister:The product will be transferred to the oven, the height of the hoister according to the oven to determine.

6.Multi-Layer Oven:The oven is mostly electric oven, the temperature between 0-200 degrees through the control cabinet self-regulation, the interior is stainless steel double mesh bag, baking time can be adjusted according to the speed, minus moisture, increase the shelf life;

7.Hoister: After baking, transfer to the crush machine.

8.Crush Machine:Once the products are dried, they are fed through crush machine. The crush machine breaks the product into small, uniform crumbs.

9.Viberate Sizer:The bread crumbs are then sieved to remove any large pieces or debris that may have been produced during the crushing process.The bread crumbs are sorted by size and texture to ensure a consistent product.

10.Packaging:Finally, the bread crumbs are packaged and prepared for shipping to retailers and other food manufacturers.

- Telephone+8613256674591

- Email[email protected]

- WhatsApp+8613256674591

- WeChat13256674591

- AddressC623, Jiahui Global Plaza, No. 548, Beiyuan Street, Tianqiao District, Jinan City, Shandong Province

- Factory AddressADD -300m North of Zhangxia Industrial Park, Binhe Road, Zhangxia Town, Changqing District, Jinan