Home > Food Processing > Industrial Microwave Gelatin Drying Technology

Industrial Microwave Gelatin Drying Technology

April 25, 2023Introduction Of Microwave Gelatin Drying Machine:

Microwave gelatin drying machine is a specialized equipment designed for the purpose of drying gelatin using electromagnetic waves. Microwave gelatin drying machine utilizes a technique known as microwave radiation to dry the gelatin without altering its chemical properties. The design of the equipment includes a microwave generator, a conveyor belt, and a heating chamber. Once the gelatin is placed on the conveyor belt, the machine emits electromagnetic waves that rapidly heat and dry the gelatin. The process is efficient and fast, with a typical drying time ranging from minutes to hours depending on the amount of gelatin being dried. The advantages of using a microwave gelatin drying machine include uniform drying, reduced production time, and the ability to preserve the natural properties of the gelatin. Additionally, the machine is energy-efficient and easy to operate, making it an ideal choice for gelatin manufacturers seeking a fast and reliable drying solution.

Parameter Of Microwave Gelatin Drying Machine:

| Equipment Model | LY-100 Industrial Microwave Drying Machine For Gelatin |

| Rated Input Apparent Power | Customization |

| Height Of Conveyor | 600-1000mm |

| Inlet And Outlet Height | 40-100mm |

| Width Of Conveyor Belt | 750±100mm(Custom-Made) |

| Microwave Leakage Standard | ISO≤5mw/Cm² |

| Operating Frequency | 2450±50Hmz |

| Transmission Speed | 0~10m/Min(Adjustable Frequency) |

Feature Of Microwave Gelatin Drying Machine:

1.Microwave radiation technology: The machines use microwave radiation technology to dry the gelatin, which is a fast and efficient method.

2.Uniform drying: The drying process is uniform and consistent, ensuring that the gelatin is evenly dried without any over or under-drying.

3.Preservation of natural properties: The microwave drying technique preserves the natural properties of the gelatin, such as its texture, aroma, and taste.

4.Energy-efficient: The machines are energy-efficient, using lower amounts of energy compared to traditional drying methods.

5.Easy to operate: The microwave gelatin drying machines are easy to operate and require minimal technical skills.

6.Automated system: The machines have an automated system that controls the drying process, ensuring that the gelatin is dried to the required level.

7.Compact design: The microwave gelatin drying machines are designed to be compact and can fit into smaller spaces.

8.Stainless steel construction: The machines are made from high-quality stainless steel, making them durable and long-lasting.

Overall, the features of microwave gelatin drying machines make them an ideal choice for gelatin manufacturers who need a fast, efficient, and reliable drying solution.

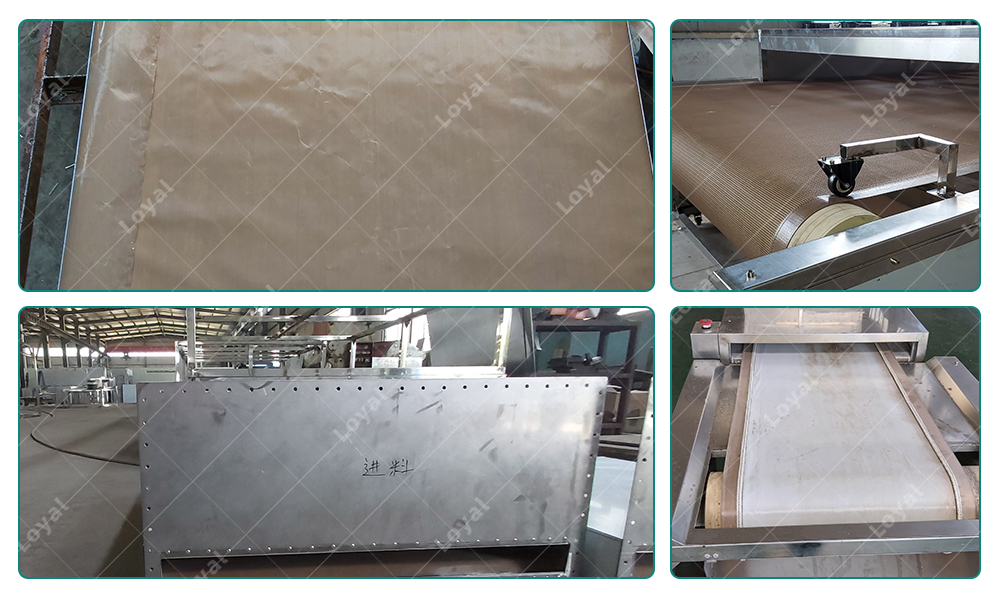

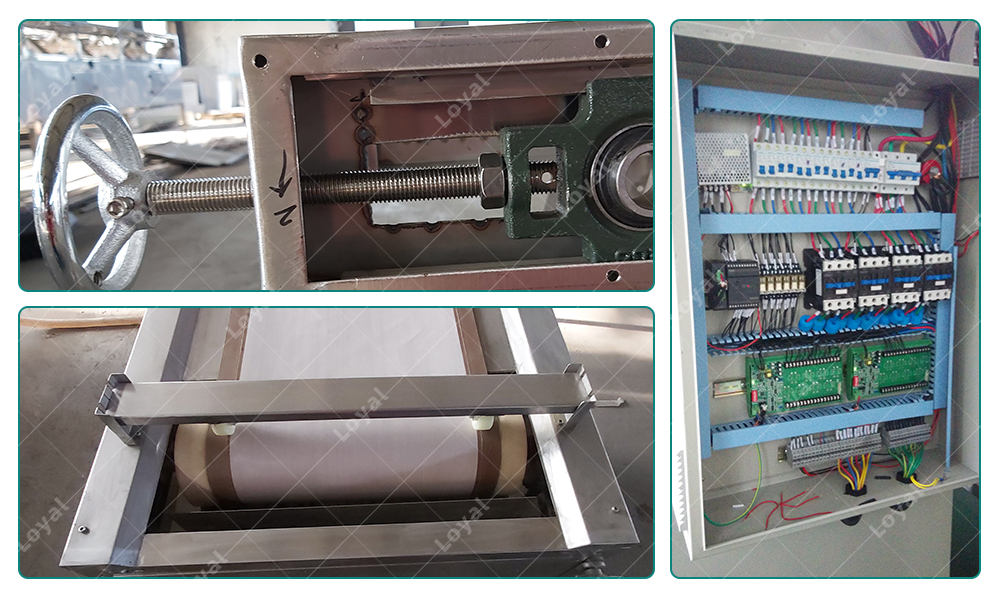

Details Displays Of Microwave Gelatin Drying Machine:

Applications Of Microwave Gelatin Drying Machine:

1.Gelatin production: The machine can be used in the production of gelatin, which is used in the manufacture of confectionery, pharmaceuticals, cosmetics, and other food products.

2.Drying fruits and vegetables: The machine can also be used for drying fruits and vegetables, which preserves their natural flavors, colors, and nutrients.

3.Drying seafood: The microwave gelatin drying machine can be used for drying seafood such as fish, shrimp, and squid.

4.Drying grains and cereals: The machine is suitable for drying grains and cereals such as rice, wheat, and corn.

5.Drying meat products: The machine can be used in the drying of meat products such as jerky, smoked meats, and sausages.

6.Drying herbs and spices: The machine is capable of drying herbs and spices, which are used to flavor food products.

7.Drying tea leaves: The machine can be used for drying tea leaves, preserving their aroma and flavor.

Overall, the microwave gelatin drying machine has a wide range of applications in the food industry, offering a fast, efficient, and reliable method of drying various food products.

Advantages Of Loyal Microwave Drying And Sterilization Equipment:

1.Energy Efficient: The equipment uses less energy compared to traditional drying and sterilization methods, reducing energy costs and contributing to a more sustainable food manufacturing process.

2.Improved Product Quality: Microwave drying preserves the natural flavors, colors, and nutritional benefits of the food, resulting in a higher quality end product.

3.Uniform Drying and Sterilization: Microwave technology allows for even and consistent drying and sterilization, ensuring that all parts of the food are treated equally.

4.Reduced Microbial Load: Microwave sterilization can effectively eliminate harmful bacteria and pathogens from the surface of the food, ensuring that it is safe for consumption.

5. Increased Shelf Life: The reduction in moisture and microbial load can result in an extended shelf life of the food, reducing waste and enhancing food safety.

6. Versatility: Microwave drying and sterilization equipment can be used for a wide range of food products, including fruits, vegetables, meats, and grains, making it a more versatile tool in the food processing industry.

Overall, the benefits of microwave drying and sterilization equipment make it a valuable and cost-effective investment for food manufacturing companies looking to improve efficiency, quality, and safety.

- Telephone+8613256674591

- Email[email protected]

- WhatsApp+8613256674591

- WeChat13256674591

- AddressC623, Jiahui Global Plaza, No. 548, Beiyuan Street, Tianqiao District, Jinan City, Shandong Province

- Factory AddressADD -300m North of Zhangxia Industrial Park, Binhe Road, Zhangxia Town, Changqing District, Jinan