Home > Food Processing > The macaroni production line is trustworthy

The macaroni production line is trustworthy

November 5, 2021Macaroni is a very popular food. Many people like to eat this kind of food because it is not only delicious, but also very convenient. With it, it can be used for cooking, frying, cold dressing, and with some other ingredients and ingredients. It can be said to be very Delicious, to a large extent can meet the needs of consumers.

Food processing plants generally use the Macaroni Production Line when producing this kind of food. The previous macaroni production process has some drawbacks, but with the advancement of technology, these drawbacks are gradually eliminated. Today’s macaroni production process has been greatly improved. The macaroni production line introduced today is very advanced and trustworthy.

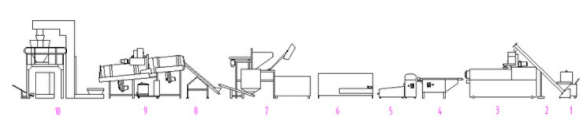

As shown in the figure, the macaroni production line adopts advanced screw extrusion technology, and the whole machine is made of food-grade stainless steel, which has been greatly improved in terms of appearance, quality and performance. Its unique technology, reasonable configuration and stable performance are very suitable for the processing and production of small and medium-sized enterprises, which can bring great convenience.

Features of the macaroni production line:

- The screw is made of alloy steel and special technology, which is durable.

- It adopts building block structure, which can be combined according to different needs.

- Forced lubrication system to ensure longer transmission life of the equipment.

- The automatic temperature control system makes the temperature control more intuitive and the parameters more accurate.

- With strong self-cleaning ability, it can be cleaned without disassembly when the machine is stopped.

- The main extruder adopts frequency conversion speed regulation, with high degree of automation and stable performance.

The working principle of the macaroni production line:

The raw materials are mixed with precise ingredients and water, and the extrusion stage is carried out with a specially designed screw system to ensure the best semolina extrusion. Once the dough is kneaded to the desired consistency, it will be cut into different lengths through a suitable mold to produce the desired shape, and the low-temperature and long-term drying system removes the water from the pasta. After the dried pasta is cooled and stabilized, it is transported to the warehouse or directly packaged.

The macaroni production line is mainly composed of a mixer, a screw conveyor, a screw extruder, a dryer, a cooler, and a packaging machine. The connection between the various equipment is very complete and stable, and the work can achieve perfect coordination and stable operation. As long as the correct operation method is followed, the smooth progress of the production process can be ensured, and the work efficiency is extremely high.

Technical parameters of the macaroni production line:

| Model | Installed Power | Actual Power | Output | Size |

| A-100 | 55KW | 43KW | 100kg/h | 21000*3000*3500mm |

| A-120 | 60KW | 48KW | 120kg/h | 23000*3000*3500mm |

The macaroni production line has a variety of models to choose from. The above technical parameters are only for reference. Its performance indicators in all aspects are very good, with low energy consumption and high production efficiency. It has a compact structure and a small floor space, which can save working space for food processing plants. During the operation, it does not require too much manual intervention, and only one or two people can complete the production of macaroni.

The macaroni making machine mainly uses wheat flour or corn starch as the main raw material. By changing the mold, it can produce various shapes of screw extruded food popular on the market, such as crisp peas, shells, spirals, square tubes, round tubes, waves, etc. The macaroni machine can complete the maturation, extrusion, and molding in one step without the need of a boiler. The product has a crystal clear appearance, crystal clear, and delicious after cooking.

The Macaroni Production Line introduced today is a very trustworthy and good equipment to own. Once it was sold, it was snapped up by customers. With its own advantages, it has won a broad sales market and is very popular both at home and abroad. If you also need this aspect, don’t hesitate, this production line is your best choice.

- Telephone+8613256674591

- Email[email protected]

- WhatsApp+8613256674591

- WeChat13256674591

- AddressC623, Jiahui Global Plaza, No. 548, Beiyuan Street, Tianqiao District, Jinan City, Shandong Province

- Factory AddressADD -300m North of Zhangxia Industrial Park, Binhe Road, Zhangxia Town, Changqing District, Jinan