Home > Food Processing > What is the feed production process?

What is the feed production process?

September 30, 2021The feed industry in our country has been developing very well for a long time. With the advancement of science and technology, the equipment for producing feed has also been developed, and the equipment is developing in the direction of more advanced, higher quality and better performance. The Feed Production Line came into being. With its own advantages, it is very popular in the feed industry.

The feed production line is advanced equipment specially used to produce various feeds. The feed pellet production line can be used to produce various poultry feeds and aquatic feeds such as dogs, cats, rabbits, ducks, cows, chickens, sheep, pigs, pigeons, fish, shrimps, etc. It is widely used in feed plants, breeding plants, and organic fertilizer plants. The feed produced is very high-quality, and excellent production results can be obtained.

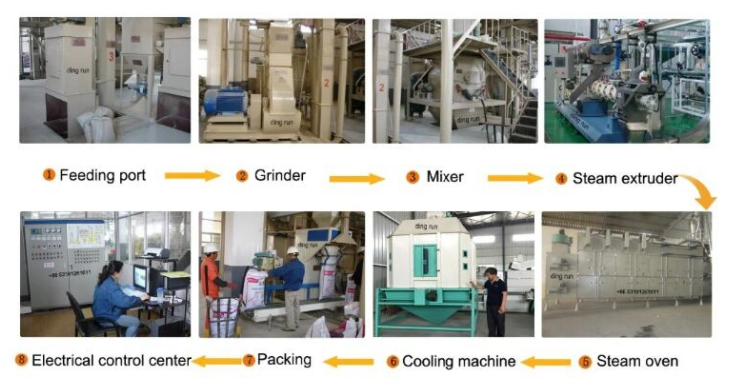

As shown in the figure, it is the feed production line. The production line is beautiful in appearance. The whole machine is made of stainless steel. It uses the most advanced parts and has a long service life. It can reduce production costs and bring high economic benefits. The production of this line is introduced in detail below. Craft.

Feed pellet processing technology:

Raw material → feed crushing → feed mixing → feed pelletizing → pellet cooling → pellet crushing → screening and grading → pellet packaging

Composition of feed pelletizing production line:

Feed grinder → mixer → pelletizer → countercurrent cooler → feed pellet grinder → grading screen → automatic weighing and packaging machine

The production process is as follows:

- Feed pelleting raw materials

It can process a variety of animal feed materials, such as corn, soybeans, wheat bran, sorghum, bones, fish, straw meal, chopped grass, etc.

- Raw material crushing process

The feed crusher crushes the raw materials to the required particle size. Different types of crushers have different crushing degrees, which can be selected according to the actual situation.

- Feeding mixing process

Mixing is a very important part of the feed processing process. Proper mixing can improve the uniformity of the feed, thereby improving the quality of the feed.

- Feed pelletizing process

Feed pelletizer is the main equipment of the entire production line. Common ring die feed pelletizers and flat die feed pelletizers. Ring film pelletizers are suitable for mass feed production, and flat film pelletizers are suitable for small-scale feed. Production.

- Feed cooling process

The feed pressed by the feed pelletizer is hot and wet. They cannot be crushed, sieved or packaged immediately. After cooling, the temperature and moisture of the feed are reduced, and the following steps are performed.

- Feed pellet crushing process

Different types of feed have different sizes, and some large ones need to be crushed into smaller ones. Commonly used are roller feed pellet mills, double-roll feed pellet mills, and three-roll feed pellet mills. Choose according to your needs.

- Feed screening and grading process

The crushed feed particles are inconsistent in size, and some have some powder. After the feed particles are screened and classified, qualified feed particles without fine powder can be obtained.

- Feed packaging technology

The last step of the feed pellets is packaging, and after packaging, it is transported, stored or sold. The automatic weighing and packaging machine can automatically weigh and pack the pellets with high precision.

The Feed Production Line adopts a fully automatic PLC control system, which has high production efficiency and easy operation. By changing the mold and formula, the feed can have different shapes and tastes. Because the feed pellets are made under high temperature conditions, the production process is pollution-free. Therefore, the quality of the feed is very high, and the taste is also excellent, which is very popular in the animal feed market.

The above is an introduction to the processing technology of the feed pellet production line. I believe everyone has a certain understanding of this after reading it, and I hope it will be helpful to you.

- Telephone+8613256674591

- Email[email protected]

- WhatsApp+8613256674591

- WeChat13256674591

- AddressC623, Jiahui Global Plaza, No. 548, Beiyuan Street, Tianqiao District, Jinan City, Shandong Province

- Factory AddressADD -300m North of Zhangxia Industrial Park, Binhe Road, Zhangxia Town, Changqing District, Jinan