Home > Application > Industrial Microwave Sterilizer

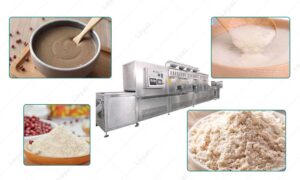

Industrial Microwave Sterilizer

August 10, 2023

General Introduction to Microwave Sterilization

Microwave sterilization is a method that uses microwave radiation to kill bacteria and viruses. Microwaves are electromagnetic waves with a high frequency and short wavelength that generate heat quickly. In the process of microwave sterilization, food or items are placed in the field of microwave radiation, and microwave energy generates heat through the molecular vibration of food or items, thereby destroying the biological activity of bacteria and viruses.

Microwave sterilization has many advantages. First of all, microwave sterilization is fast, which can quickly kill bacteria and viruses in a short time, thereby extending the shelf life of food. Secondly, microwave sterilization does not need to add chemicals, and will not change the nutritional content and taste of food. In addition, microwave sterilization equipment is small in size, easy to operate, easy to control and manage, and is widely used in food processing and medical fields.

However, microwave sterilization also has some limitations and precautions. First of all, microwave radiation has different killing effects on different types of bacteria and viruses, so it needs to be adjusted according to specific conditions. Second, microwave sterilization may not be effective enough for some heat-tolerant bacteria and spores. In addition, microwave sterilization equipment is expensive and requires professional operators to operate and maintain it.

In general, microwave sterilization is a fast, efficient and chemical-free sterilization method, which is widely used in food processing and medical fields. It provides us with a safe and convenient means of food preservation and disinfection.

Microwave sterilization is a common food processing method with many advantages, as follows:

| Efficient and fast | Microwave sterilization can kill bacteria and viruses in a short time, usually only a few minutes to complete. Compared with traditional heating and sterilization methods, microwave sterilization is more efficient and faster. |

| Maintain nutrition | Microwave sterilization can be carried out at a lower temperature, which can effectively maintain the nutritional content of food. Compared with traditional high-temperature sterilization methods, microwave sterilization can better preserve the nutritional value of food. |

| Uniform heating | Microwave sterilization heats the inside and outside of the food at the same time through the conduction of electromagnetic waves, ensuring uniform heating of the food. This helps kill microorganisms and prevents food from being damaged by localized overheating. |

| Maintain food quality | Microwave sterilization can better maintain the taste and flavor of food. Compared with traditional high-temperature treatment methods, microwave sterilization can reduce food spoilage and quality loss. |

| Environmental protection and energy saving | Microwave sterilization does not require additional chemical substances, and can be sterilized only by the heating effect of electromagnetic waves. This not only reduces the pollution to the environment, but also saves energy consumption. |

In general, microwave sterilization has the advantages of high efficiency and quickness, maintenance of nutrition, uniform heating, maintenance of food quality, environmental protection and energy saving. It plays an important role in food processing and food safety.

Industrial microwave equipment is a high-tech equipment widely used in various fields of industrial production. Its main uses include the following aspects:

| Heating and drying | Industrial microwave equipment can achieve fast and uniform heating and drying processes by transferring microwave energy to moisture molecules inside objects. This finds wide application in areas such as food processing, wood drying, textile treatment and more. |

| Sterilization and inactivation | Microwave radiation has high temperature and pressure sensitivity and can effectively kill microorganisms such as bacteria, viruses and parasites. Therefore, industrial microwave equipment is widely used in the sterilization and inactivation process of food, medicine, medical equipment and other fields. |

| Synthesis and chemical reaction | Microwave radiation can accelerate the chemical reaction, increase the reaction rate and product yield. Industrial microwave equipment has been applied in the fields of organic synthesis, catalytic reaction and nanomaterial preparation, providing new development opportunities for the chemical industry. |

| Melting and sintering | Microwave energy has fast and uniform heating characteristics, which can be used in the melting and sintering process of metals, ceramics and other materials. This has important application value in metallurgy, ceramic industry and other fields. |

| Extraction and concentration | Microwave radiation can be used to extract active ingredients in plants, such as herbal medicine extraction, essential oil extraction, etc. At the same time, industrial microwave equipment can also be used in the liquid concentration process to improve production efficiency. |

In general, industrial microwave equipment has a wide range of applications, including food processing, sterilization and inactivation, chemical synthesis, melting and sintering, and extraction and concentration. It plays an important role in improving production efficiency, saving energy, improving product quality, etc., and has an important role in promoting industrial production.

- Telephone+8613256674591

- Email[email protected]

- WhatsApp+8613256674591

- WeChat13256674591

- AddressC623, Jiahui Global Plaza, No. 548, Beiyuan Street, Tianqiao District, Jinan City, Shandong Province

- Factory AddressADD -300m North of Zhangxia Industrial Park, Binhe Road, Zhangxia Town, Changqing District, Jinan