Home > Production Lines > Biscuit Production Line > Fully automatic biscuit production line

Fully automatic biscuit production line

-

We are a professional manufacturer of food machinery, snack machines. Feed machinery, vegetable processing machinery, meat processing machinery and so on. We have been working in the field of food machinery for more than 15 years. 22 experienced engineers work for us, researching new machines, designing for customers and commissioning equipment for customers.A 24-hour service and 15 after-sales staff help our customers to resolve any problems with our machines as quickly as possible.

- Donghe

- JinanShandong

- 1 set

- A deposit of 40% and the remaining 60% upon receipt of your bill of lading

- Instructional videos available, after-sales service

- Shipping

- Qingdao Chian

| Brand Name: | Donghe | Place of Origin: | JinanShandong | Min.Order Quantity: | 1 set |

| Payment Terms: | A deposit of 40% and the remaining 60% upon receipt of your bill of lading | Supply Ability: | Instructional videos available, after-sales service | Delivery Detail: | Shipping |

| Port: | Qingdao Chian |

Introduction :

Biscuits are food products made from cereal flours (and/or pulses, potato flours) with or without added sugar, fats and other ingredients, blended (or battered), shaped, baked (or fried), and with cream, egg whites, cocoa, chocolate, etc. added between (or on the surface of, or within) the products before or after cooking.

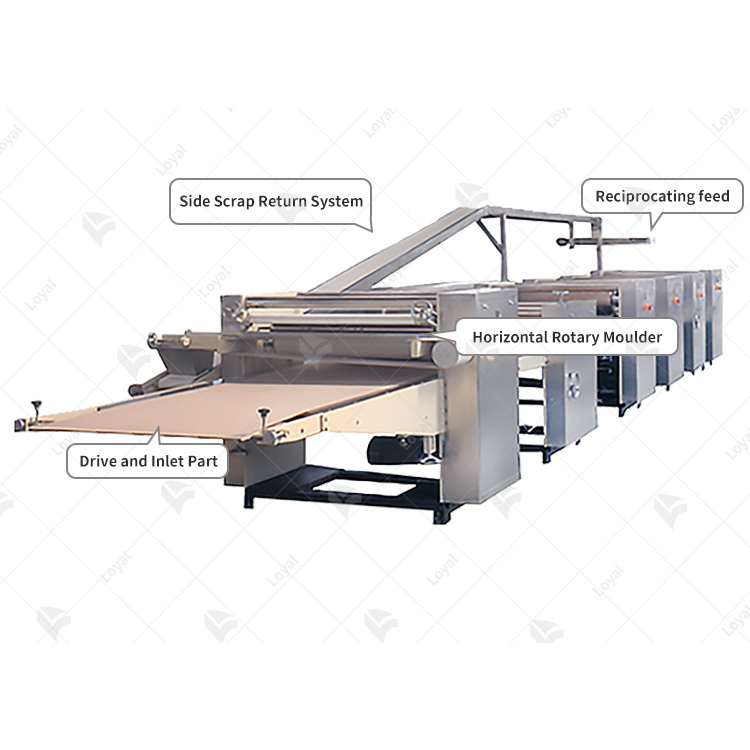

The biscuit production line is composed of biscuit forming machine, tunnel type hot air circulation electric baking oven, oil spraying machine, turning machine, cooling line, biscuit finishing machine, biscuit sandwiching machine and packing table. The whole line is controlled by CPU module, back hung motor drive, compact structure and high degree of automation, from feeding, three presses, forming, sieving sugar, conveying, scrap, recycling. Baking, oil spraying and cooling are all done automatically with electromechanical integration.

The Production Line Details:

| Capacity | 50-60KG/h; 150-200KG/h; 200-250KG/h; 400-500KG/h; 600-800KG/h; 1000KG/h; 2000KG/h |

| Electricity supply | Customized according to your local electricity situation. |

| Machine details | 1. Stainless steel,:201, 304, 316, on request.

2. Electrical components can be ABB, Delta, Fuji, Siemens; famous brands. |

| Certificates | CE,GOST,TUV,BV |

| Raw material | Wheat flour, Sugar, Eggs, Relaxing Agent, Milk Powder, etc. |

| Product colour | Brown, yellow, black, etc. |

Ingredients of biscuits and their classification:

The main ingredient in biscuits is wheat flour, to which are added sugar, fats, eggs and dairy products. Depending on the recipe Depending on the recipe and production process, sweet biscuits can be divided into two categories: hard biscuits and soft biscuits. hard biscuits are characterised by The shape of the mould is mostly concave, with pinholes on the surface. The surface of the product is flat and smooth, and the cross-sectional structure has layers. The biscuit has a crunchy feel and is chewy and crunchy. The sugar and fat content of hard biscuits is lower than that of crisp biscuits. Generally less than 30% of sugar and less than 20% of oil is used. soft biscuits are characterised by a convex mould shape with a distinctive pattern and a fine structure. The biscuit is characterised by a convex shape, with an obvious pattern and a fine structure, and is made with 14% to 30% of the flour. For some sweet and loose specialities, the oil The amount of oil used can be as high as about 50%.

Flow Chart of Automatic Biscuit Production Line:

Mixing of flour, eggs, sugar and seasonings – -Dough mixing — Biscuit forming (Rolling And Cutting) — Oven baking– Oil spraying–Cooling conveying- -Sorting- -Sandwiching–Packing.

Flow Chart Diagram:

Feature Of Automatic Biscuit Production Line:

- High degree of automation: The bread crumb production line has a very high degree of automation, which can well meet the needs of customers and fully meet the needs of various enterprises.

- Large output: It can realize multiple batch processing, thus avoiding problems such as equipment downtime and long downtime due to different batches. The output of the equipment is large, thus ensuring the production efficiency and quality. At the same time, the production speed of the equipment is fast, and the output can be adjusted at any time according to the output needs of different users.

- Low energy consumption: It can effectively reduce the utilization rate of energy and achieve the purpose of saving costs.

- Sanitation and cleaning: The equipment adopts a new type of dust removal equipment, which can well avoid dust pollution to the surrounding environment and ensure environmental hygiene. In the process of processing, a certain amount of dust will be generated. If the dust is not effectively removed, the dust will cause harm to the health of the workers.

- Easy to operate: The device is easy to operate and easy to use, whether it is a small-scale enterprise or a large-scale enterprise, it can be easily used.

The above are the characteristics of the bread crumb production line. This equipment has the advantages of large output, high efficiency and low energy consumption, and can meet the needs of various customers.

Introducing Shandong Loyal Industrial Co Ltd.

We are a professional manufacturer of food machinery, snack machines. Feed machinery, vegetable processing machinery, meat processing machinery and so on. We have been working in the field of food machinery for more than 15 years. 22 experienced engineers work for us, researching new machines, designing for customers and commissioning equipment for customers.A 24-hour service and 15 after-sales staff help our customers to resolve any problems with our machines as quickly as possible.

- Feed Production Line

- Low Temperature Baking Dog Food Making Machine

- Corn Flakes Production Line

- Baby Food Production Line

- Snack Food Production Line

- Snack Food Extruder Machine

- Biscuit Production Line

- Cereal Bar Production Line

- Fried Snack Production Line

- Soya Meat Making Machine

- Bread Crumbs Production Line

- Kurkure Production Line

- Rice Production Line

- Industrial Microwave Food Processing Line

- Macaroni Production Line

- Wafer Biscuit Production Line

- Shandong Loyal Industrial Co.,Ltd.

- Telephone+8613256674591

- Email[email protected]

- WhatsApp+8613256674591

- WeChat13256674591

- AddressC623, Jiahui Global Plaza, No. 548, Beiyuan Street, Tianqiao District, Jinan City, Shandong Province

- Factory AddressADD -300m North of Zhangxia Industrial Park, Binhe Road, Zhangxia Town, Changqing District, Jinan

Wafer biscuit production line

Wafer biscuit production line Nutritious and delicious soft biscuit production process

Nutritious and delicious soft biscuit production process Components of biscuit production line.

Components of biscuit production line. 304 Stainless Steel Complete Biscuit Production Line for Walnut Cake Biscuits

304 Stainless Steel Complete Biscuit Production Line for Walnut Cake Biscuits