Home > Production Lines > Cereal Bar Production Line > CE ISO9001 Nutrition Bar Manufacturing Equipment For Puffed Rice Bars

CE ISO9001 Nutrition Bar Manufacturing Equipment For Puffed Rice Bars

-

As a professional nutrition bar manufacturing equipment manufacturer, our cereal bars production line design good manufacturing process. Cereal bars production line can take oats, rice, black rice, sugar, nuts, corn, barley , wheat, dry fruit, raspberry, blueberry, passionflower and others as raw materials to make the cereal bar for sales. It is popular in the market because of delicious taste, crisp texture, rich nutrition and convenient portability. It has also become the main meal replacement food for fitness people. How to make cereal bars easily?

- Loyal

- PFE-65-1 PFE-70-1 PFE-85-1 PFE-90-1...

- Shandong, China

- 1 set/Cereal Bar Production Line

- L/C,T/T,D/P

- 30days /Cereal Bar Production Line

- Wooden case or wooden pellets depended on clients' requirement

| Brand Name: | Loyal | Model Number: | PFE-65-1 PFE-70-1 PFE-85-1 PFE-90-1... | Place of Origin: | Shandong, China |

| Min.Order Quantity: | 1 set/Cereal Bar Production Line | Payment Terms: | L/C,T/T,D/P | Supply Ability: | 30days /Cereal Bar Production Line |

| Packaging Details: | Wooden case or wooden pellets depended on clients' requirement |

The nutrition bar manufacturing equipment adopts PLC operating system and advanced mechanical structure to realize full automatic production-continuous feeding, automatic flattening, automatic cutting and cross cutting. Compared with traditional hand-made methods, it reduces a lot of production costs, improves production efficiency.

By changing the raw material formula, the nutrition bar manufacturing equipment can manufacture many different type products, such as cereal bars, granola bars, peanut candy bars, puffed rice bars, nougat bars, etc. The bar shape can be circular, square, semicircular and triangular.

HOW TO MASS PRODUCE CEREAL BAR ?

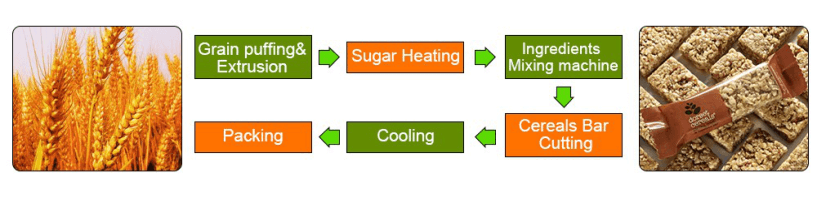

Cereal bar manufacturing process

| Raw Material | Black Rice, Sugar, Nuts, Corn, Barley, Wheat, Dry Fruit, Raspberry, blueberry, passionflower |

| Finished Products | Cereal Bar, Granola Bar, Peanut Candy Bar, Puffed Rice Bar |

CEREAL BAR MANUFACTURING PROCESS MACHINE FLOW CHART CHART

Grain puffing&Extrusion→Sugar Heating →Ingredients Mixing machine→Cereals Bar Cutting →Cooling→Packing

CEREAL BAR

| No. | Name | Function |

| 1 | Grain puffing machine | Grain puffing machine is specially suitable for puffing and expanding various rice, corn, barley, wheat, bean, maize etc. |

| 2 | Sugar heating machine | Melting and mixing the sugar or other additives (salt, cocoa, milk, etc.). |

| 3 | Mixing machine | Mixing the sugar and other material uniform together for following cutting. |

| 4 | Cereals bar cutting machine with cooling conveyor | Spreading the mixture onto the conveyor, cooling the spreaded mixture and cutting them into required sizes, cooling the cutted bars and conveying them to packing. |

| 5. | Pillow type packing machinery | Suita ble for automatic packaging candy, bread, hamburger, puffed snack food, cookies, biscuits and so on. |

| Tem | Voltage | Size(L*W*H) | Output | Machine material |

| CBC-1 | 380 | 15×15×60mm | 300~500kg/h | Stainless steel |

| CBC-2 | 380 | 15×15×60mm | 500~800kg/h | Stainless steel |

| Function of cereal bar cutting machine | Spreading the mixture onto the conveyor, cooling the spreaded mixture and cutting them into required sizes, Cooling the cutted bars and conveying them to packing. |

SAMPLES MADE BY CEREAL BAR PRODUCTION LINE

WHY SELECT CEREAL BAR MACHINE TO INSTEAD OF TRODITIONAL HAND-MADE METHOD?

Feature of cereal bar cutting machine

1.Easy Operation–Adopts advanced computer touch screen, plc control, variable frequency speed control and automatic deviation of product parameters with convenient operation.

2. Fully automatic–It adopts continuous automatic feeding, flattening,dicing and conveying.

3. Strong Quality–The machine frame is made of standard heavy profiles through welding, ensuring sufficient rigidity and strength. The external part is made of 304 stainless steel.

4. Mutifunctional –One line can make cereal bar snack,peanut candy.

THE ADVANTAGE OF NEW ENERGY BAR MACHINE

| Item | Second generation energy bar making machine | First generation energy bar making machine |

| Material | 304 stainless steel. | 201 stainless steel. |

| Control System | Adopts advanced computer touch screen, plc control | Button |

| Automatic | Fully automatic,continuous feeding, flattening,dicing and conveying | Semi automatic |

| Finished Product | Cereal bar snack, peanut candy in different size | Finished bar in one size |

AUTOMATIC CEREAL BAR CUTTING MACHINE VS SEMI-AUTOMATIC CEREAL BAR CUTTING MACHINE

| Item | Automatic protein bar machine | Semi-Automatic protein bar machine |

| Output | 300-800kg/h | 50-100kg/h |

| Need labour | 1 worker | 2-3 workers |

| Speed | Frequency | Constant speed |

| Finished Bar size | Various Type | One Size |

| Cooling System | With cooling conveyor | Without cooling conveyor |

| PLC | Have PLC control | No PLC |

| System | Including Feeding,cutting ,cooling system | Only Cutting |

- Feed Production Line

- Low Temperature Baking Dog Food Making Machine

- Corn Flakes Production Line

- Baby Food Production Line

- Snack Food Production Line

- Snack Food Extruder Machine

- Biscuit Production Line

- Cereal Bar Production Line

- Fried Snack Production Line

- Soya Meat Making Machine

- Bread Crumbs Production Line

- Kurkure Production Line

- Rice Production Line

- Industrial Microwave Food Processing Line

- Macaroni Production Line

- Wafer Biscuit Production Line

- Shandong Loyal Industrial Co.,Ltd.

- Telephone+8613256674591

- Email[email protected]

- WhatsApp+8613256674591

- WeChat13256674591

- AddressC623, Jiahui Global Plaza, No. 548, Beiyuan Street, Tianqiao District, Jinan City, Shandong Province

- Factory AddressADD -300m North of Zhangxia Industrial Park, Binhe Road, Zhangxia Town, Changqing District, Jinan

Customizable cereal , protein or granola bar production line

Customizable cereal , protein or granola bar production line Nutritious and delicious nutrition bar production line

Nutritious and delicious nutrition bar production line