Home > Technical Blog > High-Efficiency Microwave Drying and Sterilization Machine for Condiment Seasoning Sauce: A Technological Leap Forward

High-Efficiency Microwave Drying and Sterilization Machine for Condiment Seasoning Sauce: A Technological Leap Forward

January 13, 2024Introduce

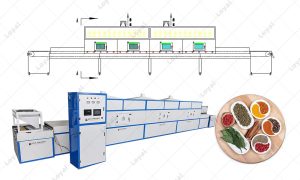

Condiments The condiments and condiments industry is at a crossroads of development, moving forward with changing needs and innovation. Central to this transformation is the critical role that drying and sterilization play in enhancing the entire spice production process. This article introduces a breakthrough solution, a high-efficiency microwave drying and sterilizing machine for condiments and sauces, that promises to redefine standards and bring the industry into a new era of efficiency.

Our company’s microwave sterilization equipment leverages advanced technology inspired by DanTech UK Ltd and Püschner.

As the industry strives for excellence, drying and sterilization processes are proving critical to ensuring the highest quality product. This article introduces a breakthrough solution to improve these processes: a high-efficiency microwave drying and sterilizing machine for condiments and sauces.

Technological miracles revealed

In the field of condiment production, the machine’s technology marks a paradigm shift. Microwave drying and sterilization takes center stage, delivering leaps in efficiency and precision. This highly efficient machine has features that redefine the condiment production landscape, including unparalleled speed, energy efficiency and a level of precision unachievable with traditional methods. Comparative analysis reveals the superiority of this machine, making it a technological marvel.

Simplify production processes

This section explains how high-efficiency microwave machines are revolutionizing condiment seasoning production through sophisticated automation. The machine significantly reduces processing time and energy consumption, improves quality and safety standards for condiment products, and ensures a seamless and efficient production workflow.

Key advantages for condiment manufacturers

Condiment manufacturers that start adopting efficient machines can expect to have a transformative impact on their operations. These benefits go far beyond mere efficiency gains and encompass key aspects that are redefining the condiment and condiment production landscape.

Taking a bold step into the future, condiment manufacturers are witnessing significant gains in productivity with efficient machines. The machine’s automated processes and rapid drying capabilities help speed up production cycles, allowing manufacturers to meet growing demand without compromising quality.

As technology takes center stage, reliance on manual labor decreases significantly. Efficient machines automate complex processes, reducing the need for extensive manual intervention. This not only streamlines operations, it also reduces the burden on the workforce, allowing technicians to focus on tasks that require human expertise.

Real-world impact: case studies and testimonials

Case studies highlight instances where a condiment manufacturer seamlessly integrated efficient machinery into its production process. From established industry players to start-ups, these success stories highlight the adaptability and universal applicability of machines across different scales of operations.

Praise and recognition from industry experts reinforce the machine’s efficiency and reliability. These reviews provide a third-party perspective on the machine’s performance, durability and overall contribution to raising the bar in condiment and seasoning production.

The real-world impact is quantifiable and improvements can be measured through production efficiency and product quality. Metrics such as reduced processing time, energy savings and improved product consistency clearly paint a clear picture of the positive impact of efficient machines on the bottom line.

Address industry concerns

This article addresses myths head-on and dispels misconceptions about the safety and effectiveness of microwave drying and sterilization. Provide clear, evidence-based explanations to reassure manufacturers about the reliability and safety of efficient machines.

To ensure a seamless transition, emphasis is placed on safety measures integrated into the machines. From automated safety checks to fail-safe mechanisms, condiment manufacturers can trust the technology to prioritize the well-being of their employees and products.

Detailed strict quality assurance protocols assure manufacturers that product quality will not be compromised. This highly efficient machine is rigorously tested to meet industry standards, giving you confidence in its ability to consistently deliver high-quality sauces.

Provide practical insights to address potential challenges in the manufacturing process. Whether adapting to different flavor viscosities or solving common problems, manufacturers can gain valuable knowledge to navigate the initial stages of this innovative technology.

Future trends and innovations

Looking to the future, this section discusses expected advances in condiment production technology. Exploring the integration of smart manufacturing systems with efficient microwave drying heralds a future of increasing overall efficiency and product quality.

Frequently Asked Questions about High-efficiency Microwave Drying and Sterilizing Machine for Condiments and Sauces

What is the difference between high-efficiency microwave machines and traditional drying methods in condiment production?

High-efficiency microwave machines use advanced microwave technology to ensure faster, more energy-efficient drying compared to traditional methods. Its precision in preserving flavor and maintaining product quality makes it stand out in the condiment and condiment industry.

What are the safety measures during microwave drying and sterilization?

Safety is the most important issue. The machine has multiple safety features including automatic controls, temperature monitoring and fail-safe devices to ensure a safe working environment. Rigorous testing and compliance with industry standards further validates its safety protocols.

Does the high-efficiency function adapt to different seasoning changes?

Absolutely. One of its main advantages is the ability to customize drying and sterilization parameters to accommodate different flavoring variations. This flexibility enables manufacturers to efficiently meet specific market needs.

Are there any notable success stories from condiment manufacturers adopting this technology?

Numerous success stories highlight the positive impact of efficient microwave ovens on condiment production. Manufacturers report significant increases in productivity, lower labor costs, and improvements in the overall quality of sauces.

What are the development trends in the field of condiment production technology in the future?

Innovation is expected to continue in the future. Anticipated trends include further advancements in microwave technology, further integration with smart manufacturing systems, and a permanent commitment to improving overall efficiency and product quality in the condiment industry.

In conclusion

In summary, the emergence of high-efficiency microwave drying and sterilizing machines is a technological leap in the production of condiments and condiments. As we navigate the ever-changing industry landscape, embracing such innovations becomes not only an option, but a necessity for those seeking to stay ahead of the curve. This transformative machine paves the way for greater efficiency, higher quality and future condiment production reaching unprecedented heights.

- Telephone+8613256674591

- Email[email protected]

- WhatsApp+8613256674591

- WeChat13256674591

- AddressC623, Jiahui Global Plaza, No. 548, Beiyuan Street, Tianqiao District, Jinan City, Shandong Province

- Factory AddressADD -300m North of Zhangxia Industrial Park, Binhe Road, Zhangxia Town, Changqing District, Jinan