Home > Food Processing > Professional Corn Flakes Making Machine With Custom-Design Service

Professional Corn Flakes Making Machine With Custom-Design Service

May 18, 2023Introduction of Corn Flakes Making Machine:

Corn is an annual herbaceous plant, also known as shrub, cob, and corn, and is used as a staple food in some regions. Corn is a healthy addition to coarse grains and is quite beneficial to human health. Niacin and other components in corn have properties that stimulate gastrointestinal motility and speed up fecal excretion, preventing constipation, enteritis and bowel cancer. Breakfast cereal cornflakes are made from corn flour as the main raw material, adding sugar, various vitamins and minerals, and a certain amount of water, which is fully kneaded, squeezed, pressed, dried, baked at high temperature and coated with sugar to form proper flakes. In modern processing, a twin-screw extruder is usually used to accomplish adequate kneading and cooked cutting of the water-added corn flour mixture. Tortilla chips are now a popular, convenient and healthy food. All you need is a bowl, some milk, a spoon, a spoonful of sugar and a box of cornflakes and you are ready to enjoy a delicious breakfast.

The new cornflake production process has the advantages of short production process, time saving, low production cost and low investment in equipment. In addition, the product has the characteristics of stable quality and long shelf life.

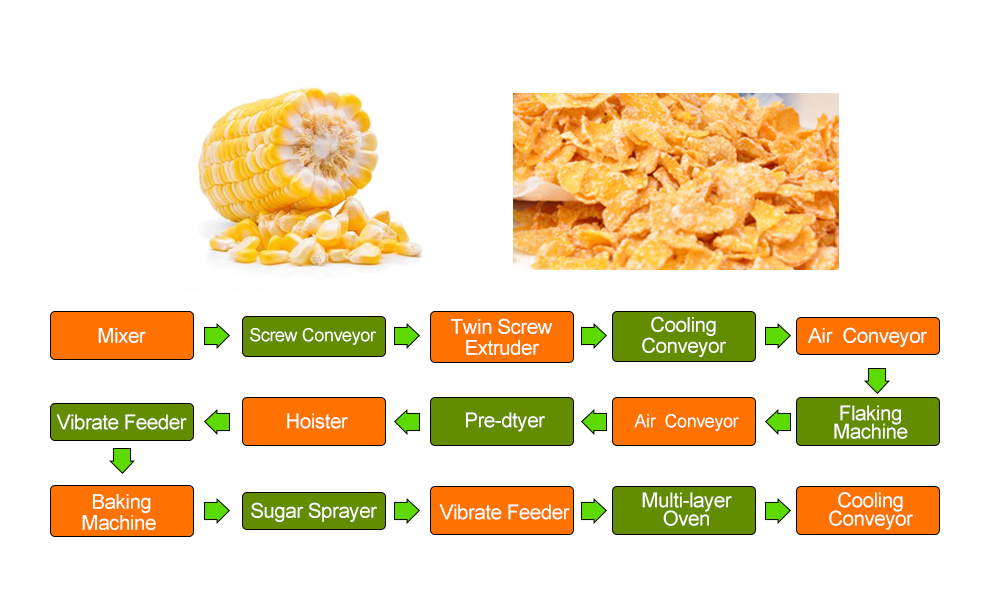

The whole corn flakes production line can automatically complete the production from mixer, screw conveyor,twin screw extruder, cooling conveyor,air conveyor,flaking machine,air conveyor,pre-dryer,hoister,vibrate feeder,baking machine,sugar sprayer,vibrate feeder,multi-layer oven and cooling conveyor to the finished product.

Details of the production line:

| Production capacity | 120-1000kg/h |

| Electricity supply | Customised according to your local electricity situation. |

| Machine details | 1.Stainless steel:201, 304, 316, on request.

2.Electrical components can be ABB, Delta, Fuji, Siemens, famous brands. |

| Certificates | CE,GOST,TUV,BV,SGS |

| Shapes | Rings balls chocos curls,etc |

Flow chart of Corn Flakes processing line:

Mixer-Screw Conveyor-Twin Screw Extruder-Cooling Conveyor-Air Conveyor-Flaking Machine-Air Conveyor-Pre Dryer-Hoister-Vibrate Feeder-Baking Machine-Sugar Sprayer-Vibrate Feeder-Multi Layer Oven- Cooling Conveyor.

Features of the Corn Flakes processing line:

1.Productivity:automated system for controlled and stable production on a continuous basis, easy and quick product change, automatic start-up, simple cleaning and maintenance procedures.

2.Economical: low investment, quick results.

3.Environmental protection: moderate output and energy saving.

4.Intelligent control system: PLC control of production to ensure optimum process parameters for each recipe.

5.Automatic lubrication system can reduce power consumption and prolong service life.

Parameters of the Corn Flakes Production Line:

| Model | Installed Power

(KW) |

Power Consumption

(kw) |

Capacity

(kg/h) |

Dimension

(m) |

| LY65 Corn Flakes Production Line | 140 | 90 | 120-150 | 39000*1200*2200mm |

| LY70 Corn Flakes Production Line | 160 | 120 | 180-220 | 41000*1500*2200mm |

| LY85 Corn Flakes Production Line | 190 | 140 | 300-500 | 43000*3500*4300mm |

| LY 90Corn Flakes Production Line | 240 | 190 | 800-1000 | 65000*5000*4300mm |

- Telephone+8613256674591

- Email[email protected]

- WhatsApp+8613256674591

- WeChat13256674591

- AddressC623, Jiahui Global Plaza, No. 548, Beiyuan Street, Tianqiao District, Jinan City, Shandong Province

- Factory AddressADD -300m North of Zhangxia Industrial Park, Binhe Road, Zhangxia Town, Changqing District, Jinan