Home > Food Processing > What are the features of Automatic Macaroni Pasta Production Line?

What are the features of Automatic Macaroni Pasta Production Line?

November 15, 2021Macaroni is a very popular pasta product in the market. And even though times have changed. Society has developed, macaroni is still one of the most promising foods in the market. With a very large market demand.

We have many years of experience in the macaroni industry. And in order to further improve the quality of our macaroni and enhance brand awareness. We decided to use more advanced equipment for production. After some market research. We found the Automatic Macaroni Pasta Production Line to be superior. It has many advantages that cannot be matched by traditional equipment.

What are the features of Automatic Macaroni Pasta Production Line?

- Made of food-grade stainless steel, reliable, durable and long-lasting.

- With a fully automated production method. The production efficiency is very high. The output per unit of time is greater. Which can help manufacturers to obtain more orders.

- It can process and produce many types of macaroni. Which is very widely used and the market competitiveness will be further enhanced.

- The equipment on the production line is compact and occupies a small area. Which can be easily used even in a small workshop. Further saving the site area.

- The installation and disassembly are very convenient. And the building block structure system can be used with other equipment. Which is very simple and convenient to use.

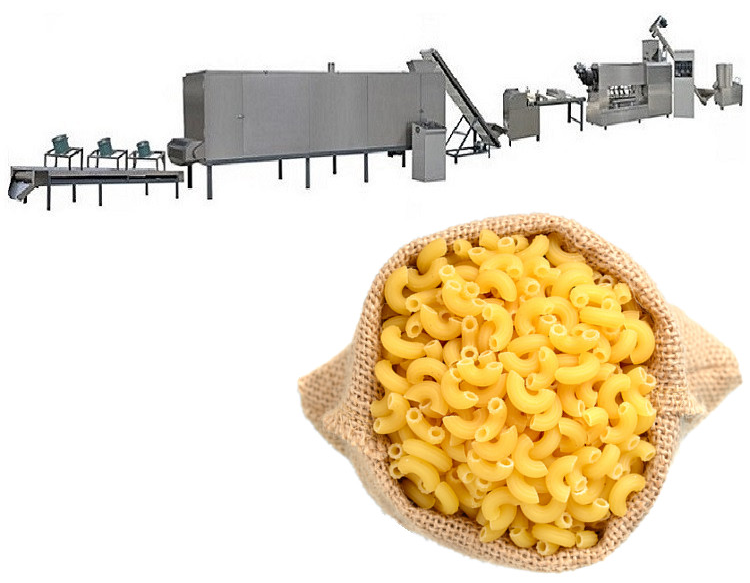

The fully automatic macaroni is a combination of mixer, screw conveyor, twin-screw extruder, vibrating screen, elevator, dryer, cooler and packaging machine, etc.

When using, we can combine these equipment for use. Also with some other equipment. The building block structure system makes the use of the equipment very simple.

After a period of use, we found many unique advantages of the equipment. Especially compared with some traditional equipment. The advantages of the automatic macaroni production line is very obvious.

What are the differences between a fully automatic macaroni line and a traditional machine?

The most obvious difference.Fully automated macaroni production line has significantly higher production efficiency.The fully automated production method can provide greater output. Resulting in orders and market share that are unmatched by traditional equipment.

Because the fully automated macaroni production line uses a mechanized production method. The production process only needs to be programmed in advance. To achieve large-scale batch production. Resulting in higher and more stable quality macaroni. That meets the needs of modern consumers.

Automatic macaroni operation is also very simple. Failure rate is very low. Maintenance is also very convenient. The energy consumption in the production process is lower. Is a very cost-effective equipment. While the traditional equipment in the use of the process of failure rate is higher. The waste of raw materials is also more serious. The use of higher costs, in a comprehensive manner less cost-effective.

Since we have been using Automatic Macaroni Pasta Production Line. Our process has improved significantly. The macaroni we produce is more recognized in the market. The market size has been further expanded and the brand awareness has increased significantly.

The manufacturer not only customized the equipment for us. Also provided very perfect after-sales service. Which solved all the problems we had in using it. And provided us with great convenience. We hope that with the help of the manufacturer. We can become one of the most influential enterprises in the food processing industry. And we also hope that the manufacturer can develop better and better. So that we can jointly promote the prosperity of the food processing industry.

- Telephone+8613256674591

- Email[email protected]

- WhatsApp+8613256674591

- WeChat13256674591

- AddressC623, Jiahui Global Plaza, No. 548, Beiyuan Street, Tianqiao District, Jinan City, Shandong Province

- Factory AddressADD -300m North of Zhangxia Industrial Park, Binhe Road, Zhangxia Town, Changqing District, Jinan