Home > Food Processing > What is extrusion technique?

What is extrusion technique?

June 28, 2021The extrusion technique is widely used in life because it has many superior processing characteristics. It can realize the continuous production of conveying, stirring, mixing, crushing, cooking, sterilizing, and pressurizing conditions.

So what is the extrusion technique? Let’s get to know the relevant content of extrusion technology together.

Extrusion technique refers to the process in which materials are pre-treated (crushed, moistened, mixed) and then mechanically forced to pass through a specially designed orifice (die opening) to form a product of a specific shape and organization. Because of the many advantages of food processed by Food Extruder Machine, it has been widely used in the food processing industry and has developed rapidly.

The main features of the Food Extruder Machine:

1, Good versatility

It is possible to obtain various food products by changing the material variety, formula, and processing conditions on the same extruder machine.

2, Large production capacity

An extruder machine provides a continuous processing device from conveying to extrusion with a small footprint but a much larger production capacity than any other cooking and forming apparatus of the same volume.

3, Low cost

The labor, equipment space, and energy consumption required per unit of product are smaller than other steaming and forming devices, resulting in low cost and high efficiency.

4, Various product shapes

The extruder can produce various shapes that are difficult to make by other processing methods by changing the die head and cutting method.

5, High product quality

High temperature, high pressure, short time processing makes a starch paste and protein denaturation. Thus, the digestibility of food is changed. This processing generates the minimum loss of food nutrition and simultaneously destroys most undesirable factors in the food and sterilization effect.

6, High energy utilization

Extrusion forming processing device is in the case of relatively low moisture content in the material to steam various food. Therefore, it can reduce the energy consumed by cooking and re-drying food after cooking immensely.

7, The production of new food is easy

The extruder can make protein, starch, and other food ingredients modified to produce new products.

8, almost no loss of food ingredients

Extruder under strict control is almost into the number of raw materials on the number of products, no raw material loss in the process. It does not produce pollutants, which is the key advantage of the food extrusion process.

These advantages of the extruder are in line with the sustainable development strategy of humanity and therefore are very promising. In the food industry, extrusion is the technology of producing products by extruding raw materials with sugar or protein as the main component in a

These advantages of the extruder are in line with the sustainable development strategy of humanity and therefore are very promising. In the food industry, extrusion is the technology of producing products by extruding raw materials with sugar or protein as the main component in a

sealed cylinder equipped with a screw inside, under heating and pressure, subjected to friction and shear force, changing the organization of raw materials in a short time. And then, it extruded by a specific shape of the extrusion die after cutting and cooling.

It extruded the food processing principle:

Extruded food processing process and the usual food processing of cooking, the cooking process is different, extruded food heating, cooking and extrusion forming is in an extruder, with a short time is almost completed at the same time. The general processing process is: food ingredients mixed according to different formulas, after pretreatment, into the screw extruder. Then, under the rotation of the screw, knead it into a sticky and elastic dough. Afterward, continue to be sheared and heated and under the control of the die to produce a certain pressure. The result is that starch paste, protein denaturation, enzyme inactivation, microbial reduction.

When extruding food from the die, due to the sudden pressure drop, water vapor rapidly expands and disperses, making the product form a porous structure, which is entirely different from the usual baking cookies and secondary puffing of the food maturation process, this extrusion process of particular heating, pressurization, can produce favorable effects on food, such as making the digestibility of food, fast food, mold inactivation rate tends to be maximum, while the harmful effects on food Such as browning, damage to nutrition tend to minimize.

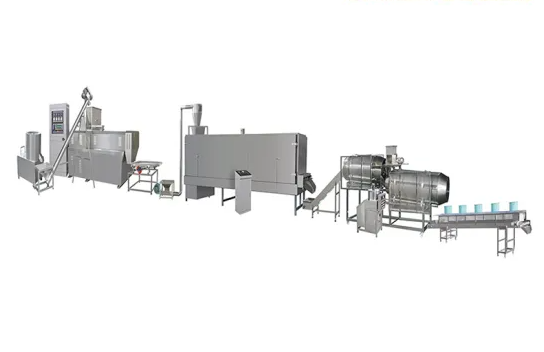

We are a manufacturer of extrusion machinery with many years of experience in production. Through our years of research, extrusion technology has been using widely in many fields. Our products include single and twin-screw extrusion snack machines, breakfast cereal and cornflake machines, fish feed machines, pet food machines, dog bite machines, fried food machines, etc.

We can provide single equipment or complete plant layouts and lines which are customized to meet customer requirements. If you have any need in this area, you can contact us at any time, and we also provide the best quality service. Your satisfaction is our pursuit.

- Telephone+8613256674591

- Email[email protected]

- WhatsApp+8613256674591

- WeChat13256674591

- AddressC623, Jiahui Global Plaza, No. 548, Beiyuan Street, Tianqiao District, Jinan City, Shandong Province

- Factory AddressADD -300m North of Zhangxia Industrial Park, Binhe Road, Zhangxia Town, Changqing District, Jinan