Home > Production Lines > Snack Food Production Line > 120kg-1200kg/h Corn Puff Making Machine/ Production Line

120kg-1200kg/h Corn Puff Making Machine/ Production Line

-

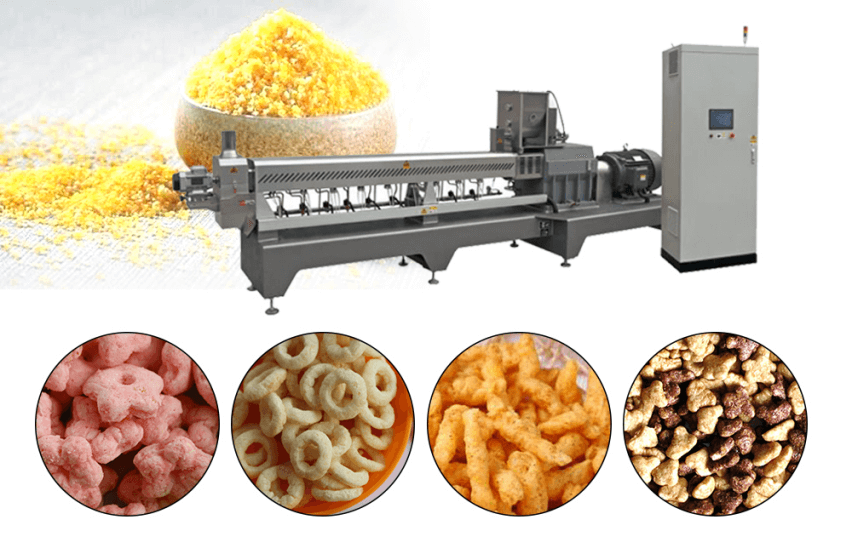

As a professional manufacturer of Corn Puff Making Machine, we have been in the field of Corn Puff Making Machine for 15 years. We are the supplier of Corn Puff Making Machine, our Corn Puff Making Machine design good manufacturing process. Corn Puff Making Machine can take corn, rice , wheat, oat, grains, potato flour, and others as raw materials, to make the cheese balls, corn curls, corn sticks, coco pops, cereal.

- LOYAL

- INM240

- Shandong China

- 1 sets/ Snack Food Production Line

- T/T,L/C,D/P

- 20days /Snack Food Production Line

- Wooden case or wooden pellets depended on clients' require

| Brand Name: | LOYAL | Model Number: | INM240 | Place of Origin: | Shandong China |

| Min.Order Quantity: | 1 sets/ Snack Food Production Line | Payment Terms: | T/T,L/C,D/P | Supply Ability: | 20days /Snack Food Production Line |

| Packaging Details: | Wooden case or wooden pellets depended on clients' require | Power(W): | 8.2kW | Certification: | CE ISO9001 |

| Warranty: | 1 YEAR | Automatic: | Snack Food Production Line | Function: | Multifunctional |

| Capacity: | 35000pcs/24H | Raw material: | Dough |

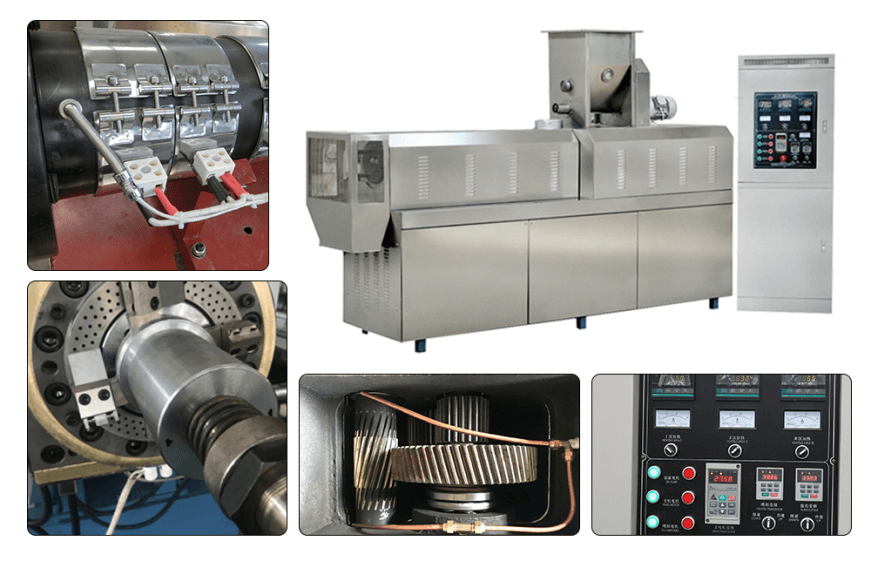

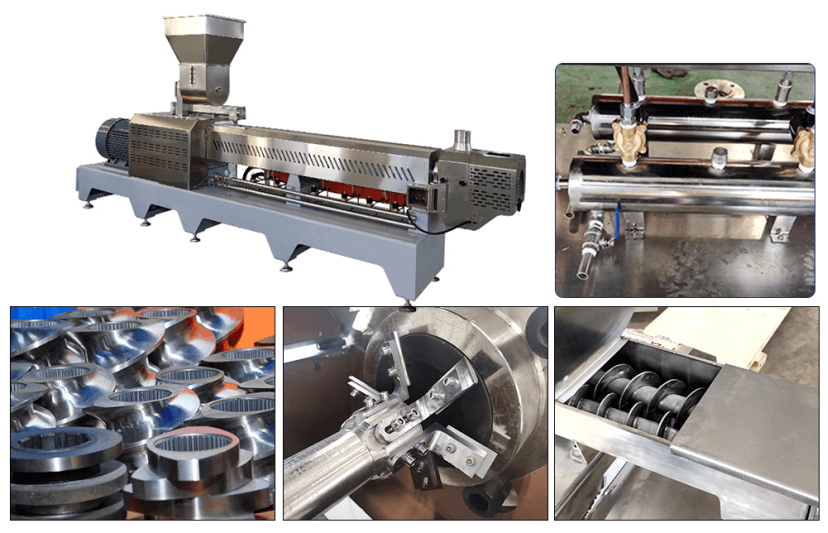

The corn puff snacks making machine manufacturing process can finish mixing, extruding, shaping, core-filling, cutting, baking and flavoring in one-pass operation automatically. By changing the moulds and process technology, this snacks production machines can making core-filled snacks, like chocolate filled bar, cream filled pillow, rice cake, cereal bar, sheet snacks for sale.

TECHNICAL PARAMETERS FOR SNACKS MAKING MACHINE

| Capacity: | 100-150g/h 200-250kg/h 300-500kg/h 300-500kg/h 800-1000kg/h |

| Converter: | customizable |

| Function: | Multifunction |

| Installation: | Engineer Guide |

| Model: | LY65 LY70 LY85 LY75 LY95 |

| Voltage: | customizable |

| Heating source for continuous dryer: | Electric/Gas/Steam |

| Key Words: | Corn Puff Making Machine |

DIFFERENT MODEL FOR SALE OF SNAKES MANUFACTURING MACHINE

| Model | Installed Power | Power Consumption | Output | Size (L*W*H) |

| LY65 | 84kw | 59kw | 120-150kg/h | 21000x1200x2200mm |

| LY70L | 132kw | 92kw | 200-250kg/h | 23000x1500x2200mm |

| LY85 | 239kw | 167kw | 300-500kg/h | 28000x3500x4300mm |

| LY75 | 186kw | 139.5kw | 400-500kg/h | 24000*2000*2800 |

| LY95 | 295kw | 222kw | 800-1200kg/h | 31000*3500*4300 |

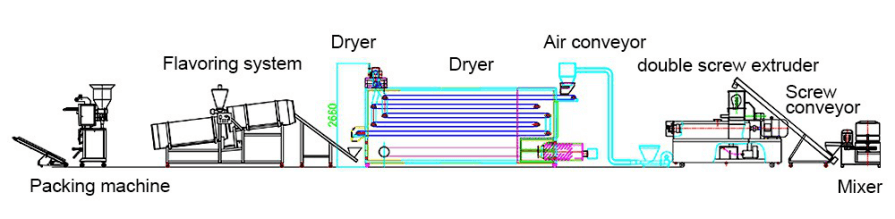

FLOW CHART OF CORN PUFF MAKING MACHINE :(from right to left) ①Flour Mixer②Screw Conveyor③Double Screw Extruder ④Air Conveyer⑤Dryer ⑥Single drum Flavoring machine Packing Machine

This line has with Mixing system, with Extrusion system, with Drying system, with Flavoring system, with Packing system.

THE APPLICATION OF CORN PUFF MAKING MACHINE The raw materials of Corn Puff Making Machine can be corn, rice, wheat, oat, rye, grains, potato flour, coco pops, cereal, etc. The color of the raw materials is different, so the products of this machine can be in multiple colors. But the raw material must be powdery. He can produce cheese balls, corn curls, corn sticks, and the product shapes produced by this production line can also be of many types: kurkure, pellets, balls, sticks shape, pillows, animals, stars, rings shape, Fried peanut shape, etc. Puff Snacks Making Machine, corn snacks food making machine, Snacks food processing line will all use this production line

THE ADVANTAGE OF CORN PUFF MACKING MACHINE Slight weight, save labor, only 1-2 workers are required. Compact structure, save space Easy operating, easy to learn Twin-screw High productivity, high efficiency Stainless steel, easy to learn

- Feed Production Line

- Low Temperature Baking Dog Food Making Machine

- Corn Flakes Production Line

- Baby Food Production Line

- Snack Food Production Line

- Snack Food Extruder Machine

- Biscuit Production Line

- Cereal Bar Production Line

- Fried Snack Production Line

- Soya Meat Making Machine

- Bread Crumbs Production Line

- Kurkure Production Line

- Rice Production Line

- Industrial Microwave Food Processing Line

- Macaroni Production Line

- Wafer Biscuit Production Line

- Shandong Loyal Industrial Co.,Ltd.

- Telephone+8613256674591

- Email[email protected]

- WhatsApp+8613256674591

- WeChat13256674591

- AddressC623, Jiahui Global Plaza, No. 548, Beiyuan Street, Tianqiao District, Jinan City, Shandong Province

- Factory AddressADD -300m North of Zhangxia Industrial Park, Binhe Road, Zhangxia Town, Changqing District, Jinan

High Productivity Jam Center Snack Food Processing Line With Coating System

High Productivity Jam Center Snack Food Processing Line With Coating System High Automatic Core Filling Snack Food Processing Line Self Cleaning, 220/380/415V

High Automatic Core Filling Snack Food Processing Line Self Cleaning, 220/380/415V